To upskill as a Digital fabrication Specialist in 2026, mastering computational design skills has become essential. Fabrication is no longer defined by manual control alone but by algorithms, parametric modeling, and automated workflows that bridge design and production. According to the U.S. National Institute of Standards and Technology, manufacturing contributed $2.3 trillion to the U.S. economy in 2026, reflecting its pivotal role in innovation and production.

As industries integrate digital tools into every stage, specialists who combine advanced software with problem-solving capabilities are positioned for success. By building expertise in Rhino, Grasshopper, Python scripting, and BIM automation tools, a digital-fabrication practitioner can meet the industry’s demand for precision, scalability, and efficiency.

The Evolving Role of Digital Fabrication Specialist

Today’s specialist translates design logic into machine action. Algorithms, parametric models, and automation link geometry to production, making computational design skills central to daily work.

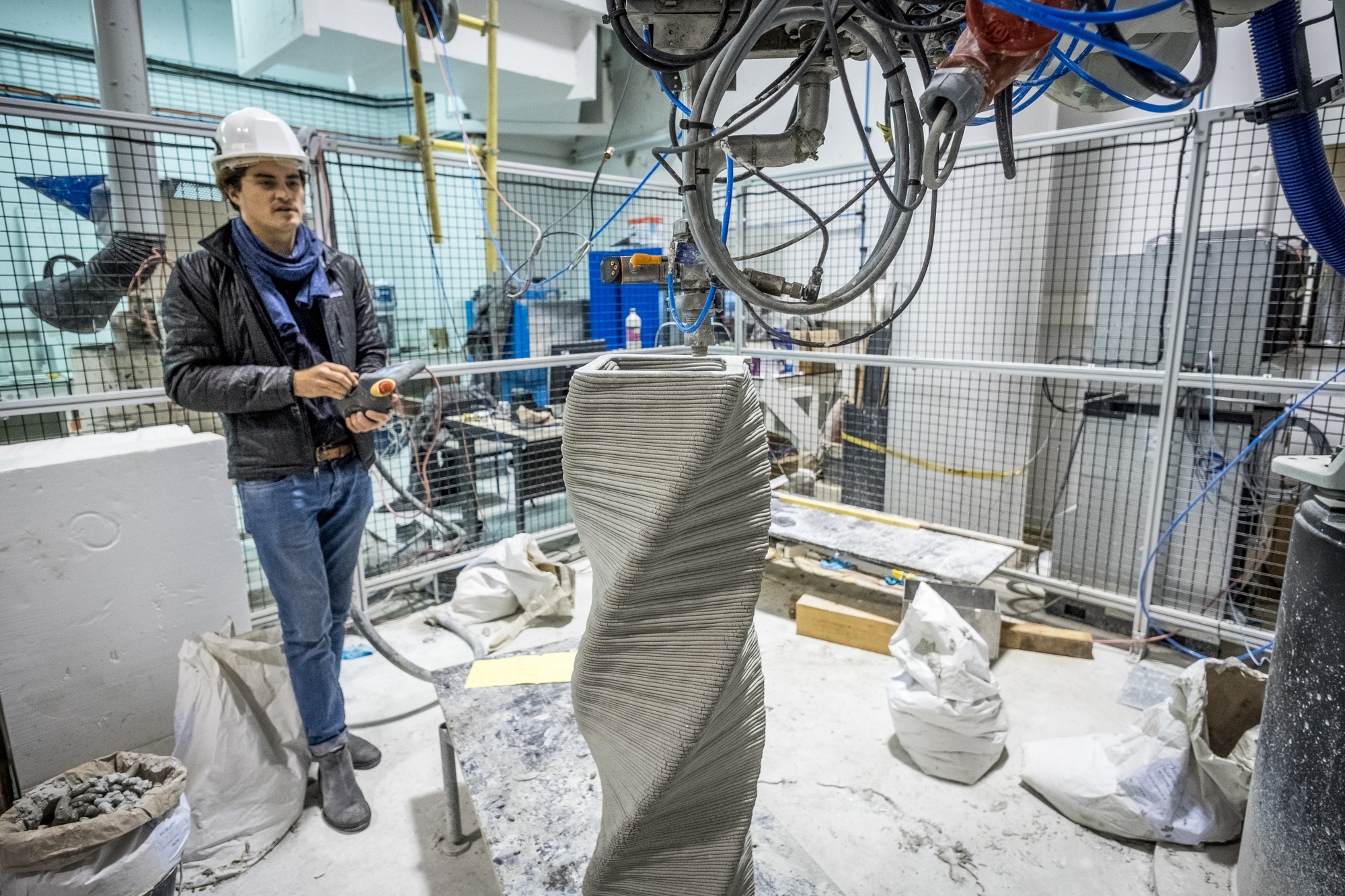

- Manage end-to-end pipelines from Rhino/Grasshopper definitions to CNC, 3D printing, and robotics.

- Convert parametric rules into reliable toolpaths, minimizing manual edits and rework.

- Use data-driven facade optimization to balance daylighting, performance, and fabrication constraints.

- Standardize scripts, templates, and checklists to capture repeatable know-how.

- Sync models with documentation through BIM process automation to keep shop outputs aligned.

These shifts elevate the role from operator to systems integrator, unlocking measurable advantages of computational design across speed, precision, and material efficiency.

Why Computational Design is the Key to Next-Level Fabrication?

Adopting computational design skills provides tangible advantages for specialists in digital fabrication. These benefits extend far beyond design speed and touch every part of the workflow.

Key advantages of computational design include:

- Rapid design updates: Parametric models allow instant adjustments to geometry, saving hours of manual editing.

- Reduced material waste: Optimized toolpaths and smart BIM process automation lead to leaner, greener fabrication processes.

- Consistency and precision: Scripts and algorithms reduce human error, delivering uniform quality across multiple runs.

- Workflow scalability: Once created, a Grasshopper definition or Python scripting solution can be applied repeatedly with minimal effort.

- Seamless integration: Linking computational tools with CNC machines, robotic arms, and 3D printers bridges design and production effortlessly.

When combined, these advantages of computational design create smarter systems that drive efficiency and unlock new creative possibilities. Specialists who adopt this mindset will find themselves more competitive and valuable across industries.

Essential Computational Design Skills to Master

To excel, a Digital Fabrication Specialist must develop both technical and interpersonal capabilities that support digital workflows. These skills determine how effectively designs transition into physical form.

Software skills

The foundation of computational workflows lies in mastering the best software for computational design.

- Rhino (Rhinoceros 3D): Known for its ability to handle complex geometry, Rhino is indispensable for creating precise, fabrication-ready models. Professionals who learn Rhino 3d gain the ability to design freeform surfaces and accurate details compatible with CNC machines and robotic fabrication.

- Grasshopper: As Rhino’s visual programming interface, Grasshopper allows parametric control and iterative exploration. Those who learn Grasshopper 3d can create systems where changing one input automatically updates the design, ideal for customized fabrication or facade optimization.

- Python scripting: Coding skills in Python unlock advanced automation. Specialists use scripts to automate repetitive processes, generate machine instructions, or connect Rhino models to BIM automation systems.

- Hardware integration: Knowing how to interface design software with CNC machines, robotic arms, or additive manufacturing systems ensures a direct pipeline from design logic to physical production.

Together, these software skills establish the backbone of modern fabrication practices.

Soft Skills

Human capabilities make automated workflows stick. Clear reasoning, collaboration, and structure ensure parametric intent survives real-world constraints.

- Structured problem framing that maps design goals into parameters and rules.

- Plain-language communication with architects, engineers, and fabricators about algorithmic intent.

- Version control and documentation for Grasshopper files and Python scripting assets.

- Cross-disciplinary coordination to align design logic with BIM automation tools and production timelines.

- Quality-assurance habits that test edge cases before sending code to machines.

Mastery of these combined skills ensures that fabrication processes are not only efficient but also innovative and sustainable. By investing in these abilities, professionals prepare themselves for advanced opportunities in digital construction and manufacturing.

Best Place To Learn Computational Design?

For those seeking structured advancement, Novatr’s Master in Computational Design Course is a production-focused path that treats parametric modeling as a buildable practice, making it a strong contender for the best place to learn computational design. The program is structured as a computational design course with direct application to fabrication. It offers a structured experience that aligns digital modeling with practical outcomes, making it a strong choice for digital fabrication specialists seeking to upskill as a Digital fabrication Specialist.

Course Key USPs

- Comprehensive skill-building in six months: Master essential computational design skills by working with Rhino, Grasshopper, scripting tools, and over a dozen industry-standard plugins. The curriculum is structured for production-ready outcomes rather than abstract experimentation.

- Mentorship from global experts: Learn directly from practitioners at leading firms such as UNStudio, Ramboll, Heatherwick Studio, Buro Happold, and Gensler, gaining practical insights into how computational workflows are applied in advanced projects.

- Project-based learning for real-world impact: Build a portfolio of live projects that reflect contemporary design challenges from parametric modeling to generative systems and automation, ensuring your knowledge is directly transferable to practice.

- Future-focused curriculum: Stay ahead of industry shifts with modules designed around evolving technologies in computational and parametric design, making this computational design course a pathway to future-ready skills.

- Career readiness and certification: Beyond technical training, the program offers career services including mock interviews, portfolio development, and LinkedIn optimization. On completion, you receive a computational design certificate and a portfolio that demonstrates your capabilities to employers.

- Team-based, flexible learning: Engage in live weekly sessions, peer collaborations, and one-on-one mentorship while managing your own schedule, making the course both interactive and adaptable.

This structure ensures the professionals learn Rhino 3d, learn Grasshopper 3d, and connect them to machines through targeted automation, graduating with assets that prove capability, not just course completion.

By combining technical mastery with hands-on fabrication, Novatr ensures that its graduates are not only software proficient but also capable of leading digital-to-physical transitions in industry. For professionals aiming to upskill as a Digital fabrication Specialist, the course stands out as the best place to learn computational design in 2026.

Conclusion

The future of fabrication belongs to specialists who combine creativity with computation. To upskill as a Digital fabrication Specialist, mastering computational design skills is the most effective step forward. By developing expertise in Rhino, Grasshopper, Python scripting, and BIM process automation, while also honing communication and problem-solving abilities, professionals can meet the challenges of advanced manufacturing.

Programs such as the Master in Computational Design by Novatr offer structured training, practical application, and portfolio development, bridging the gap between digital logic and physical output. With industries prioritizing precision and scalability, computational design provides the competitive edge specialists need to thrive.

Visit our resource page to get started and receive expert guidance on advancing your career.

Was this content helpful to you

.jpg)