What is Scan to BIM: Benefits & How It Works

Table of Contents

In this article, we will dive deep into what Scan to BIM is, how it works, its benefits, industry applications, and some real-life examples that use this process.

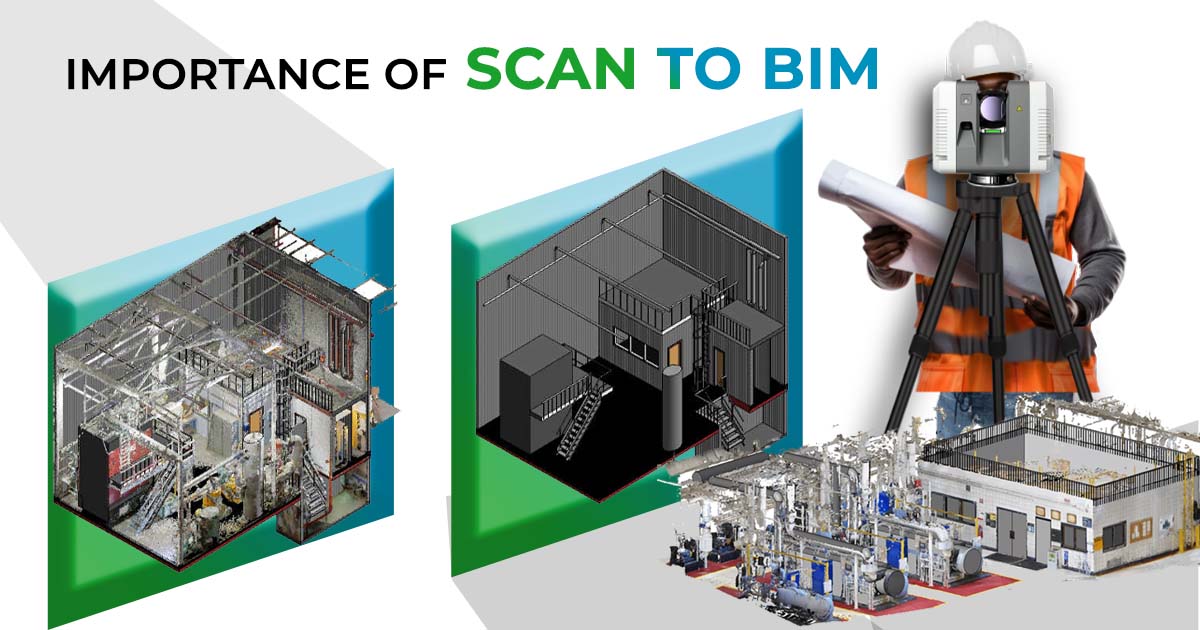

What is Scan to BIM?

Scan to BIM converts laser-scan point clouds of existing spaces into accurate BIM models for renovation, as-built documentation, coordination, and digital twins, helping teams capture real conditions faster and reduce measurement errors in complex projects.

Applications of this technique can range from as-built documentation, project renovations and additions, and facility management. The 3D models built from scan to BIM are also useful for comparing against the original project drawings, design plans, topographic registrations, and more. AEC professionals around the world are investing in BIM modeling services to derive the best possible solutions from their designs as well as the resources around them.

Read: 10 Awesome BIM Projects Around the World You Can't Miss

How Scan to BIM work?

Scan to BIM typically follows defined steps: set modelling requirements, plan scan positions, capture point clouds with laser scanners, process and clean the scan data, then convert it into a BIM model for verification and project use.

.webp?width=922&height=632&name=scan-bim1.png%20(1).webp)

1. Identification of Requirements

Before starting the scanning process, it is important to determine the requirements for the desired model. Some things to consider at this stage include the required building elements, level of detail (LOD), and the non-geometric attributes. It should be kept in mind that a higher level of design detail usually translates to a higher cost.

Read: What is Lod & Everything About it in 3D Modelling

2. Scan Planning

Before a scan commences, some key parameters need to be entered into the scanner’s touch screen interface before the acquisition of a 3D scan. The variables that need to be considered include factors such as accuracy, desired resolution, coverage, location, and angular resolution.

3. Scanning

After all the project planning, comes the process of scanning the physical space or site. This is done with the help of a 3D laser scanner, which collects the data at high speed and precision. Popular laser scanning instruments include Faro, Trimble, Riegl, and Leica.

As the invisible laser beam hits the various objects or materials present on-site, their position relative to the scanner gets recorded as a piece of digital data known as a "point." When several of these points are collected, they are commonly referred to as a “point cloud." It is a set of data points within a three-dimensional coordinate system that can accurately represent the external surface of an object or its interior environment. Point clouds begin to build a highly accurate three-dimensional digital picture of the physical space or site being scanned.

It is interesting to note that 3D laser scanners can capture the interior structure of the building as well, including concealed mechanical, electrical, plumbing, and fire protection installations. This comes in handy for professionals who wish to understand the inner workings of a building without disturbing the project.

The scanning process can be executed in various ways, like:

1. 360 degree scans: The scanner can perform a complete 360 degree rotation or a lesser turn, depending on the area to be captured.

2. Time-of-Flight Scans: It is a type of scannerless LIDAR (light detection and ranging) that uses high power optical pulses in durations of nanoseconds to capture information, typically over short distances.

4. Deciphering the Scanned Data

Once the scan is complete, the captured data can be taken out of the scanner on a simple USB drive and imported onto a computer device. These point clouds are then fed into 3D modelling software like Autodesk ReCap. This data will be stored in a .rcp file format which can then be imported into Autodesk softwares such as InfraWorks, Civil 3D, Revit, AutoCAD, and Inventor.

5. BIM Modelling

The final stage involves transforming this data into a digital representation of the project. It is a technique where the scan is illustrated with the as-built conditions of the building.

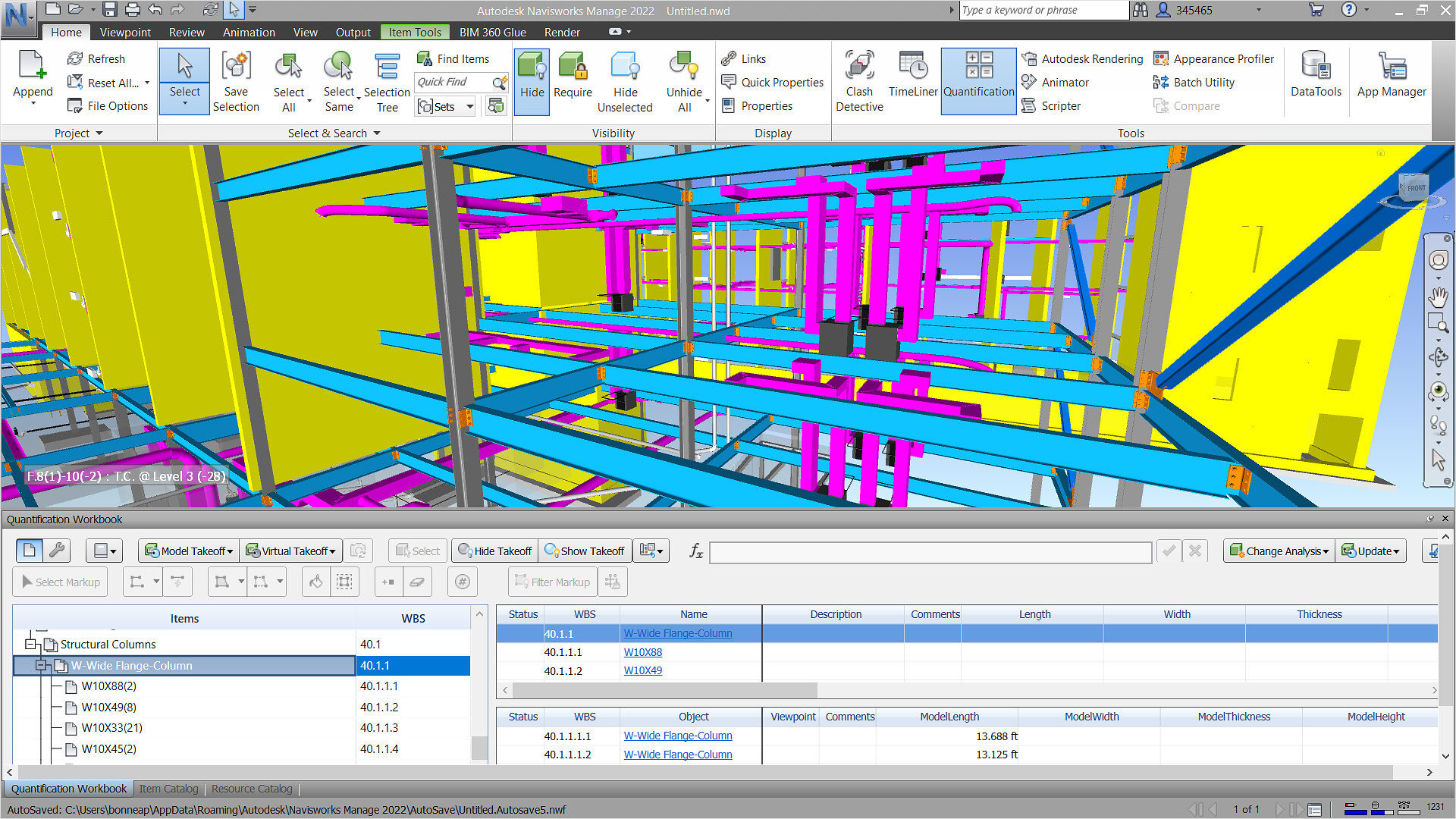

Once the Autodesk Revit model is complete, the model can be imported into Autodesk Navisworks. It can then be overlaid relative to the point cloud in Autodesk ReCap Pro for verification.

Benefits of Scan to BIM

The benefits of the process include:

1. Quick collection of data: 3D laser scanners can collect millions of data points in seconds. This makes the Scan to BIM process the quickest way to collect data.

2. Increased Accuracy: Traditionally, hand measurement methods were used for surveying. This technique was slow and often produced inaccurate results due to human error. 3D laser scanning reduces a large degree of human error by eliminating human involvement in scanning.

3. Helps tackle complex shapes and forms: With Scan to BIM, professionals can tackle enormous and complex shapes and sizes with ease.

4. Creation of a digital twin: A digital twin is a highly complex and exact virtual representation of an object or a building. The building has connected sensors that collect data which is mapped onto this virtual model. The digital twin model helps predict and map out the entire lifecycle of a building from design to demolition with utmost accuracy. The process of Scan to BIM helps with the creation of a digital twin.

5. Generation of 3D virtual assets: Point cloud 3D models help generate 3D virtual assets which can be used further for feasibility studies and collision checks with upcoming elements. They can also be used to run the construction simulation.

6. Reduced travel: A digital twin helps all the stakeholders understand and explore the site without making visits. It comes handy, especially, if the site is remotely located, allowing design professionals to invest their time in research, conceptualising and designing instead.

7. Cost efficiency: Scan to BIM helps reduce the construction cost and helps in maintaining the timeline of the projects.

8. Reduces health and safety hazards: Laser scanners can be used to collect information from dangerous or hard-to-reach locations without putting surveyors at risk. For example, in hazardous areas like sewers, laser scanners can be lowered into the pits instead of risking a person’s life.

The process of Scan to BIM can be outsourced by private and public clients to companies specializing in this domain. These services deliver accurate and parametric as-built BIM models and 2D CAD models incorporating the pipes, walls, slabs, roof plans, facades, and landscapes in and around the building.

Also Read: Architecture Thesis Topics: A Comprehensive List of 30 Topics to Pick From 2026

Autodesk software for scan-to-BIM projects

Autodesk supports scan-to-BIM workflows through tools such as ReCap Pro for point-cloud processing, Revit for BIM modelling, Navisworks for coordination and clash review, and Civil 3D for terrain and infrastructure-related modelling tasks.

Autodesk has a comprehensive set of software solutions for Scan to BIM projects, allowing professionals to convert point cloud data into accurate 3D models. Key tools that are a part of it:

1. Revit

A leading BIM software that enables users to create precise architectural, structural and MEP models from point cloud data, making it ideal for renovation and restoration projects.

2. Recap Pro

Specialises in capturing, processing and editing laser scan data. It converts raw point clouds into actionable data, allowing seamless integration with Revit and other design software.

3. Navisworks

A powerful tool for clash detection and model coordination. It allows the integration of multiple data formats, including point clouds to identify conflicts and improve project efficiency.

4. Civil 3D

Designed for civil engineering projects, it supports point cloud data processing for terrain modeling, surface creation and infrastructure design, making it essential for complex site development projects.

Challenges and Limitations

As with any emerging process, scan to BIM has certain limitations that need to be addressed. Let us look at the challenges and limitations:

1. Need of Collaboration: The Scan to BIM process is an iterative one. The client needs to be involved at every step of the way. Collaboration and communication are key. An open and frequent dialogue with the client is essential to agree on a certain Level of Detail (LOD).

2. Limitations of the software: Most BIM design tools, including Revit, are targeted at designing new buildings and it becomes difficult to effectively use them for documenting existing structures.

3. Weather limitations: There are weather limitations to the Scan to BIM process and it cannot be conducted outdoors in certain weather conditions like rain.

4. Challenges of large areas: Large areas are more difficult to scan as large data sets require adequate computing power and storage space for processing.

5. Busy areas: Scanning processes require the areas to be vacant. This can be a little difficult if the places are busy and bustling.

Industry Applications

Scan to BIM is used across the AEC industry in different disciplines like mechanical, electrical, fire safety, structure, etc.

Some industry applications of the technique include inspection before installation, planning and space optimization, structural analysis, conservation, scanning of distant objects, project supervision, volume calculation, quality control, to list a few.

Let us explore the real world applications of 3D laser scanning for BIM:

1. Architecture: Scan to BIM is extensively used in the architecture industry for three-dimensional inspection before installation, creation of as-built models for existing or new buildings, site inspection of existing environments, site analysis and planning, and planning and space optimisation.

2. Construction: The various applications of Scan to BIM in the construction industry include structural analysis, construction progress monitoring, deformations control, estimates for repair, and coordination.

3. Heritage preservation: The use of 3D laser scanners to capture a built environment comes in handy in the field of heritage preservation as well. It is used for reconstruction, restoration, and conservation.

4. Civil Engineering: Although Scan to BIM is mostly adopted by professionals in the architectural and built environment, this workflow can also be fruitful to professionals in the civil infrastructure industry. The scan to BIM workflow can be applied for scanning roads, volume calculations, clash detections, quality controls, and technical modifications.

5. Facility Management: Here, Scan to BIM is used for the documentation and planning of structural alterations. With the help of video fly-throughs or walkthroughs, facility managers can run through the usage options for rooms even before designing actually begins.

6. Forensics: Interestingly, the “Scan to BIM” process is also used in forensics, where it is used to quickly and accurately document crime and accident scenes before such areas are reopened to the public.

Read: 6 Ways BIM Is Proving To Be The Future Of Architecture

Real-life examples in the Industry

1. The St James' Church, London

Industry: Heritage conservation

Services by: B1M

Software used: Trimble Realworks

St. James Church is a heritage building in London. For its scanning, a 3D laser scanner attached to a standard tripod was used. A particularly important consideration during this heritage project's documentation was to ensure that the lasers neither affect the building material nor damage the building’s fabric. After the scanning process was complete, the scan was imported into Trimble Realworks, a powerful software tool that enables you to register, analyse and 3D model from the scan.

2. Mechanical Room of a School Facility, Florida

Industry: MEP Engineering

Services by: United BIM

Software used: Revit, Recap Pro

The purpose of the project was to recreate the 3D model of an existing mechanical room. For this, the room was scanned from multiple reference points. The point clouds were then converted into a 3D Revit BIM model (of an HVAC system). The model contained customized Revit families/joinery items, ducting systems, and HVAC components.

Also Read: 10 Common Architecture Interview Questions & How to Ace Them (2026)

3. World Trade Center, New York City

Industry: Architecture Documentation

Client: Global Designer and Manufacturer

Software used: Faro Scene, Autodesk Recap, Autodesk Revit

The World Trade Center is a large complex of seven buildings in the Financial District of Lower Manhattan in New York City. For this project, a Faro Focus 120 was used for scanning. Then, a 3D model was created in Revit. This helped spatially represent the project, simulate the proposed construction sequencing and represent the system interdependencies. As the building complex was fragmented, BIM-based visualization interfaces proved to be important tools for providing process transparency.

Future Scope

There are many different modern technologies that have come up with the growth of Scan to BIM. The technologies have greatly reduced scanning time while simultaneously increasing their areas of application. Some of the latest technologies include:

1. LIDAR

The LiDAR 3D scanner is a device that realizes 3D space scanning based on LIDAR technology. It emits multiple laser beams, which help measure the distance between the sensor and the object. Its applications include examining the surface of the earth, assessing information about the ground surface, creating a digital twin of an object, or detailing a range of geospatial information. The real-world applications of LiDAR can be classified as follows:

1. The Environment: These applications include mapping flood risk, carbon stocks in forestry, and monitoring coastal erosion.

2. Automotive: Smaller, low-range LiDAR scanners help navigate autonomous vehicles.

3. Space Travel: Interestingly, LiDAR has been identified by NASA as key in enabling them to land lunar vehicles safely.

Benefits of LIDAR:

- Weather resilient: LiDAR offers precise 3D measurement data over short to long ranges, even in challenging weather and lighting conditions.

- Resolution and Accuracy: LiDAR generates instantaneous, massive amounts of measurements, in seconds. This makes it accurate to a centimeter.

2. Mobile Laser Scanning

This is a land surveying method that makes the use of a laser system mounted on moving vehicles like buses, cars, trucks, or even UAVs. This process of scanning is mainly used for scanning landscapes, cityscapes, infrastructure, etc.

Benefits of Mobile Laser Scanning:

- No GPS Required: Modern mobile laser scanning systems do not require GPS for the orientation and recording. This is done with the application of simultaneous localization and mapping (SLAM) technology.

- Saved time: Using a terrestrial laser scanner (TLS) to capture a building requires planning the scanner position, setting it up, and breaking it back down – over and over again. Using a mobile laser scanner saves this additional time. In typical projects, mobile mapping devices offer a speed increase of 10X over terrestrial scanning.

BIM helps generate 3D virtual assets with the data collected by the 3D laser scanners. The BIM data further helps in calculating an accurate Bill of Material that diminishes the chances of a project’s construction budget overruns.

Conclusion

Scan to BIM turns real-world scan data into reliable BIM models that support renovations, retrofits, documentation, coordination, and digital twin workflows. It reduces site visits, improves model accuracy, and helps teams catch conflicts earlier, which supports safer planning and tighter timelines. As LiDAR and mobile laser scanning become more accessible, Scan to BIM will keep expanding across architecture, infrastructure, and facility management. To build strong BIM capability for modern projects, consider the BIM Professional Course for Architects offered by Novatr, which trains you on industry workflows and software used across real projects. For more insights on BIM tools, career paths, and AEC trends, visit our resource page.

FAQs

1. What does scan to BIM mean?

Scan to BIM means capturing an existing site using 3D laser scanning, generating a point cloud, and converting it into a BIM model. It is commonly used for renovation planning, as-built documentation, and accurate coordination.

2. What is the difference between CAD to BIM and scan to BIM?

CAD to BIM converts 2D drawings or CAD files into a BIM model, while Scan to BIM starts from real-world laser scans. Scan-based modelling reflects actual site conditions, even when drawings are missing or outdated.

3. Which software is used for scan to BIM?

Common tools include Autodesk ReCap Pro to process point clouds, Revit to build BIM models, Navisworks to coordinate and review clashes, and Civil 3D for infrastructure surfaces and site-related modelling when required.

4. How to use scan to BIM?

Start by defining the required LOD and scope, then plan scan locations and capture point clouds. Clean and register the scans in software, import them into BIM tools, model key elements, and validate accuracy against scans.

5. What are the benefits of scan to BIM?

Scan to BIM improves accuracy, speeds up site data capture, reduces manual measurement errors, supports complex geometry, and strengthens coordination for renovation and retrofit projects. It also enables digital twin creation and better long-term asset management.

Thanks for connecting!

Thanks for connecting!

.png)

.jpg)

.png)