Robotic fabrication is revolutionizing the field of architecture and design, transforming how we create and construct buildings, furniture, and other structures. This blog aims to delve into the fascinating world of robotic fabrication methods in architecture, exploring its applications, benefits, and notable projects that have harnessed its potential. From architectural structures to furniture designs, we will uncover how robotic fabrication has played a crucial role in creating innovative and awe-inspiring creations.

What is Robotic Fabrication in Architecture?

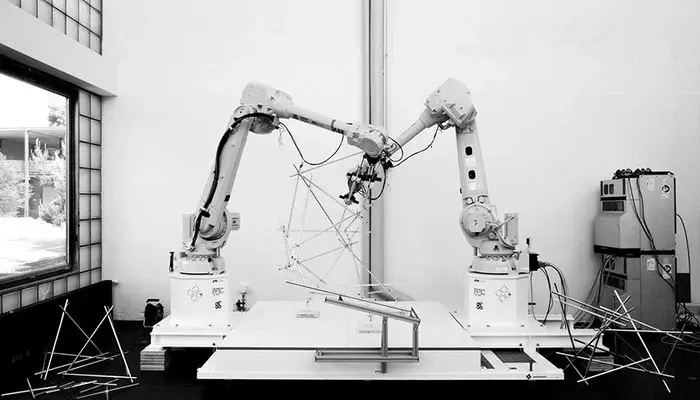

The robotic fabrication method in architecture refers to the use of robotic systems and emerging technologies to design, construct, and assemble architectural structures. It involves the integration of advanced digital technologies, such as computational design processes and tools and robotic arms, into the architectural fabrication process.

It offers architects and designers greater flexibility, precision, and efficiency in realizing complex and innovative architectural forms. It enables the creation of customized and intricate designs that would be difficult or time-consuming to achieve through traditional construction methods. The robotic systems can be programmed to perform various tasks, including cutting, milling, 3D printing, welding, and assembly, allowing for a wide range of construction possibilities.

The robotic fabrication process typically begins with the generation of a digital design model using computer-aided design (CAD) or building information modeling (BIM) software. The digital model is then translated into machine-readable instructions that control the robotic arm's movements and actions. The robotic arm, equipped with various tools or end-effectors, executes these instructions to fabricate architectural components or even entire structures.

Robotic fabrication in architecture is an emerging field that continues to evolve as advancements in robotics and digital technologies progress. It holds the potential to transform the way buildings are designed, constructed, and experienced, pushing the boundaries of architectural possibilities.

Advantages of Robotic Fabrication in Architecture

Robotic fabrication integrates robotic systems and emerging technologies into construction and design processes. It offers numerous advantages over traditional methods, including:

1. High Precision and Accuracy realizing complex designs with minimal errors. Architects can explore highly customized and unique designs by creating complex shapes and structures that were previously challenging.

2. Robotic automation streamlines construction, increasing efficiency and reducing time spent on repetitive tasks.

3. Robotic systems optimize material usage, minimizing waste and promoting sustainable construction practices.

4. Robots handle hazardous tasks, improving worker safety by reducing risks on construction sites.

5. Robotic fabrication is scalable and adaptable to different project scales and complexities, allowing for experimentation and exploration of architectural ideas and techniques.

Application and Case Studies Involving Robotic Fabrication Methods

Robotic fabrication has revolutionized various industries with its precision, efficiency, and versatility. Architecture has enabled the creation of complex, sustainable structures, pushing design boundaries. In art, it has fostered innovative sculptures and installations. Space exploration employs robotic fabrication for in-situ construction on extraterrestrial bodies. The technology aids disaster recovery by rapidly constructing temporary shelters. With applications across diverse sectors, robotic fabrication has enhanced creativity, productivity, and problem-solving capabilities, reshaping industries and advancing human potential.

Here are some examples where robotic fabrication has played a crucial role.

1. The MX3D Bridge, Amsterdam

The MX3D Bridge in Amsterdam is a significant example of robotic fabrication in architecture. Robotic fabrication played a crucial role in the construction of this fully functional pedestrian bridge over the Oudezijds Achterburgwal canal. The project utilized advanced robotic 3D printing technology to fabricate the bridge's structure. Robotic arms with 3D printing capabilities enabled the construction of the MX3D Bridge layer by layer, achieving complex geometries. Robotic fabrication optimized the design by distributing material strategically, reducing waste and weight while ensuring structural integrity. The project benefited from robotic fabrication by realizing a challenging design efficiently and creating intricate and organic shapes that met specific requirements.

Additionally, robotic fabrication improved the construction efficiency of the bridge. The ability of the robotic arm to work continuously and consistently without fatigue allowed for faster vision compared to manual labor. This accelerated the construction process, resulting in reduced project timelines and associated costs. The MX3D Bridge project showcased the potential of robotic fabrication for large-scale architectural structures by demonstrating the successful construction of a fully functional bridge.

2. DFAB House, Switzerland

DFAB House in Switzerland is a groundbreaking architectural project where robotic fabrication played a crucial role and was extensively used throughout the construction process

The project achieved high precision, efficiency, and customization by using robotic arms and advanced digital fabrication techniques. Robotic fabrication created complex and intricate architectural elements with minimal errors and waste. It enabled the 3D printing of concrete components, robotic timber fabrication, and other automated construction processes.

The use of robotic fabrication technology in DFAB House provided several benefits. Firstly, complex geometries and intricate designs that would be challenging to achieve using conventional construction methods were made possible by the efficient and precise fabrication of customized architectural elements.

Robotic manufacturing boosted productivity, and uninterrupted work, lower labor costs, and accuracy, and automation streamlines the process. The DFAB House indicated sustainable and digitally designed buildings with minimized material waste and design freedom for innovative solutions. It illustrated the benefits of robotic fabrication in architecture, showcasing intricate designs, improved efficiency, optimized material usage, and sustainable practices.

3. The Digital Grotesque II, Switzerland

"The Digital Grotesque II" is an innovative architectural project that explores the intersection of digital design, robotic fabrication, and traditional architecture. It was showcased at the Swiss Architecture Museum (SAM) in Basel, Switzerland, as a follow-up to the original "Digital Grotesque" project. In "The Digital Grotesque II," architects Michael Hansmeyer and Benjamin Dillenburger utilized advanced computational design techniques and robotic fabrication processes to create intricate and highly detailed architectural elements. The project focused on generating complex forms that would be nearly impossible to achieve through traditional architectural methods.

The project's key aspects of robotic fabrication include computational design, 3D printing, custom material and scale, additive manufacturing, and digital craftsmanship. Computational algorithms were used to generate intricate and ornate designs, while robotic arms with 3D printing capabilities were used to fabricate the architectural elements. A custom material mixture, including sand and an inorganic binder, was used, and additive manufacturing was employed to build up the material layer by layer. The term "digital craftsmanship" refers to the careful integration of digital tools and robotic fabrication methods with the artistic sensibilities and attention to detail traditionally associated with craftsmanship.

The outcome of this project was a series of incredibly intricate architectural elements, including columns, arches, and other decorative elements. All were created using advanced computational design and robotic fabrication techniques. This project challenges conventional notions of architectural design and construction and pushes the boundaries of what is achievable through the fusion of digital technology and traditional craftsmanship. It also sparks conversations about the future of architecture and the role of technology in shaping our built environment.

4. The Durotaxis Chair, Japan

The Durotaxis Chair project in Japan utilized robotic fabrication to create a chair with correct ergonomic features. Robotic fabrication played a crucial role by enabling the accurate cutting and shaping of the chair's components.

The project benefited from robotic fabrication technology by achieving a highly customized design perfectly adapted to the body's contours. The robotic arm, equipped with milling capabilities, intricately carved a wood block to create the chair with precise ergonomic details. This level of customization resulted in enhanced comfort and support for the chair's user.

Robotic fabrication also contributed to the efficiency of the project. The robotic arm's ability to precisely execute the cutting and shaping tasks ensures consistent quality and reduced the need for manual labor. It improved efficiency in production and assembly, resulting in time savings and a more streamlined manufacturing process.

Moreover, the Durotaxis Chair project demonstrated the potential for robotic fabrication to combine traditional craftsmanship with advanced technology. By leveraging robotic fabrication, the project showcased the fusion of precision and craftsmanship, creating a chair that exhibited functional and aesthetic qualities.

The Durotaxis Chair project exemplified the advantages of robotic fabrication in furniture design. The project demonstrates how robotic fabrication could improve comfort and beauty in furniture design while speeding up the production process.

5. Voxel Chair, Netherlands

The Voxel Chair is an innovative furniture design project from the Netherlands where robotic fabrication has played a crucial role. Robotic fabrication was used to create this unique and intricate chair design.

By leveraging robotic arms and advanced digital fabrication techniques, the Voxel Chair achieved several significant outcomes. Firstly, robotic fabrication enabled the precise and intricate shaping of the chair's components. The robotic arms were programmed to deposit material layer by layer, resulting in a complex voxel-based design. This level of precision and detail would have been challenging to achieve manually.

Using robotic fabrication also allowed for efficient customization and design flexibility. The parametric design of the Voxel Chair was easily adaptable to different sizes, shapes, and user preferences. Each chair could be tailored to specific requirements through computational design tools and robotic fabrication, offering a high degree of customization for individual users.

The Voxel Chair project demonstrated optimized material usage and reduced waste through robotic fabrication. Precise material deposition minimized excess material, aligning with sustainable design principles. It showcased the integration of robotic fabrication into furniture design, pushing boundaries and offering complex and customizable pieces. This benefits the design community and provides unique options for consumers.

The Netherlands' Voxel Chair project serves as a showcase for the significant contribution that robotic fabrication makes to furniture design.

In conclusion,

Robotic fabrication is revolutionizing the field of architecture and design by transforming how we create and construct buildings, furniture, and other structures. The integration of robotic systems and technologies into the architectural fabrication process offers architects and designers greater flexibility, precision, and efficiency in realizing complex and innovative designs. It offers numerous advantages. It enables precise and customized designs, streamlines construction, optimizes material usage, enhances worker safety, and allows for scalability and experimentation in architectural projects.

They showcase intricate designs, improving construction efficiency, optimized material usage, and sustainable practices. Pushing design boundaries, these projects offer new possibilities for architecture and personalized furniture design. Robotic fabrication is balanced to revolutionize the construction industry and expand architectural options. Combining robotics and digital tools will open the door to even more avant-garde inventions as technology evolves. The future of architecture and design will be shaped by robotic fabrication, providing architects and designers with new tools to bring their visions to life.

Robotic fabrication in Architecture is a new technology with numerous exciting possibilities for the AEC industry. Robotic fabrication, with its advanced capabilities such as precision, automation, and versatility, has transformed traditional construction methods. Novatr provides a Master's Computational Design course that helps you in designing complex and customized architectural elements, improves construction efficiency, reduces material waste, and opens the door to innovative designs that were previously difficult to realize.

Was this content helpful to you

-1.png)