.png)

The construction industry is evolving with smarter, faster, and more efficient MEP engineering methods. According to data from the U.S. General Services Administration, building operations consume approximately 40% of the energy and 74% of the electricity produced annually in the United States.

Modular MEP systems have emerged as an innovative approach to streamline design and installation, contrasting with traditional MEP systems, which follow a more site-dependent process. As sustainability and digital transformation continue to drive modern construction, understanding these systems and their impact on MEP system efficiency is essential for engineers and project teams seeking better outcomes.

What Are Modular and Traditional MEP Systems, and How Do They Differ?

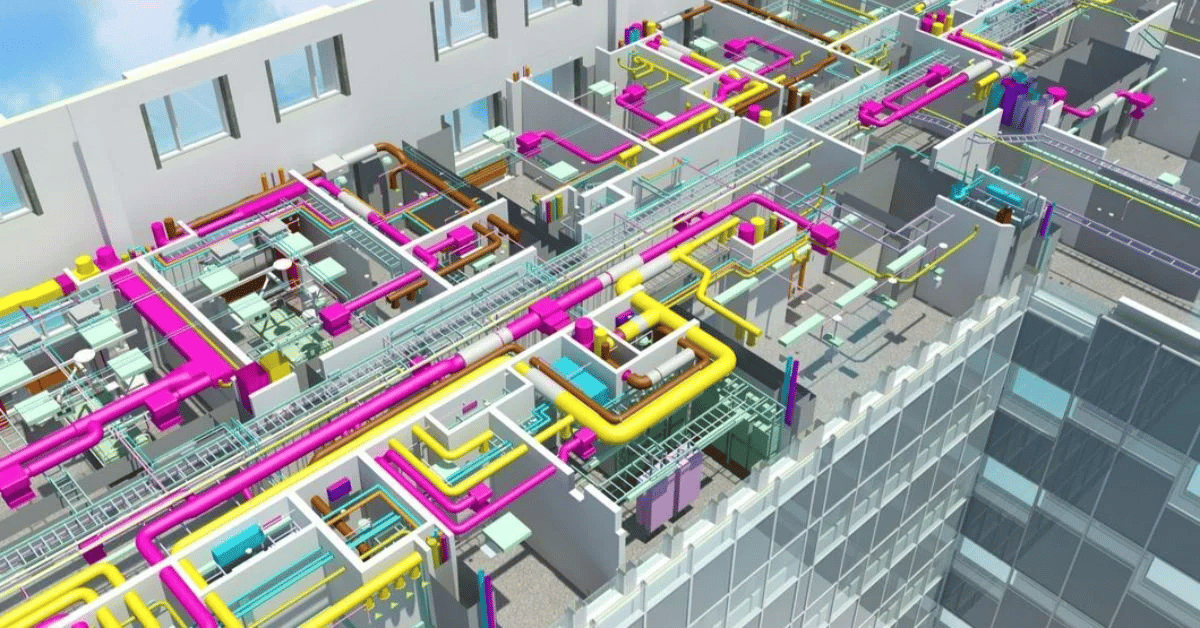

Modern construction projects rely on effective MEP coordination to ensure seamless system functionality and energy performance. Modular MEP systems use prefabrication to design, assemble, and test building service modules off-site before installation. This method ensures consistency, better planning, and faster delivery.

Key distinctions between the two include:

-

Design and fabrication: Modular systems depend on MEP software and digital tools for precise modeling, while traditional systems rely more on manual layout and installation.

-

Workflow: Modular construction allows simultaneous on-site and off-site work. Traditional MEP systems follow a sequential process that can extend project timelines.

-

Efficiency and coordination: Modular methods enable better building services integration, reducing clashes and rework.

-

Project adaptability: Traditional methods provide flexibility for on-site adjustments, especially for smaller or customized projects.

-

Sustainability: Prefabrication supports sustainable construction solutions by minimizing waste and optimizing material use.

Both approaches have their place depending on the differences between modular and traditional MEP systems, project scale, and logistical requirements. However, modular systems are rapidly gaining ground as projects demand higher efficiency and speed.

Advantages of Modular MEP Systems Over Traditional Methods

Modular MEP systems combine precision engineering with digital coordination to deliver consistent, high-quality results. These systems leverage modern fabrication technologies that improve productivity, safety, and sustainability throughout the project lifecycle.

Major advantages include:

-

Accelerated installation: Off-site production allows construction and assembly to happen simultaneously, showing clearly how modular MEP improves installation speed.

-

Quality and consistency: Controlled environments improve construction quality control in modular MEP projects, reducing errors and rework.

-

Reduced waste and energy use: Aligns with sustainable construction solutions through efficient use of resources.

-

Enhanced coordination: Digital modeling enables MEP workflow optimization using modular systems, ensuring smoother team collaboration.

-

Safety improvements: Less on-site work minimizes safety risks.

The advantages of modular MEP in construction projects are clear: faster delivery, reliable performance, and streamlined processes that contribute to efficient, sustainable buildings. This makes modular construction an ideal choice for large-scale or repetitive developments where timing and precision are crucial.

Also Read: Top 50 MEP Interview Questions & Answers 2026

Benefits and Limitations of Traditional MEP Systems

While modular methods are advancing, traditional MEP systems still play a vital role, particularly for smaller or more complex designs that require adaptability.

|

Benefits |

Limitations |

|

Flexible and suitable for unique or customized designs. |

Slower installation times compared to modular systems. |

|

Lower initial setup costs. |

Higher labor costs due to extensive on-site work. |

|

Allows direct oversight and hands-on control. |

Increased risk of coordination errors between trades. |

|

Familiar to most contractors and MEP engineers. |

Environmental impact is higher due to on-site waste. |

|

Easier to modify during construction. |

Quality can vary depending on workforce skill and site conditions. |

Traditional MEP systems, though flexible, face challenges like inconsistent scheduling, rework, and limited digital integration. Understanding their impact on construction planning helps teams decide when these methods are most suitable.

Factors to Consider When Choosing Between Modular and Traditional MEP

Selecting the right approach involves evaluating project scope, budget, and sustainability goals. A thorough construction methods comparison helps ensure that the chosen system supports project objectives and long-term performance.

Factors to consider include:

-

Project scale and complexity: Large-scale builds benefit from prefabricated building services, while smaller projects may suit traditional installation.

-

Timeframe: Tight deadlines favor modular approaches that reduce dependency on sequential site work.

-

Budget and resource planning: Modular systems require more upfront investment but deliver savings through reduced labor and waste.

-

Quality control: Controlled production supports better construction quality control in modular MEP projects.

-

Sustainability goals: Prefabrication supports sustainable construction solutions and energy-efficient outcomes.

-

Coordination: Seamless building services integration minimizes conflicts and optimizes performance.

Ultimately, the choice depends on the project’s needs, schedule, and MEP design strategies. Balancing flexibility with precision ensures better delivery outcomes for both modular and traditional methods.

Also Read: BIM for MEP: A Complete Guide 2026

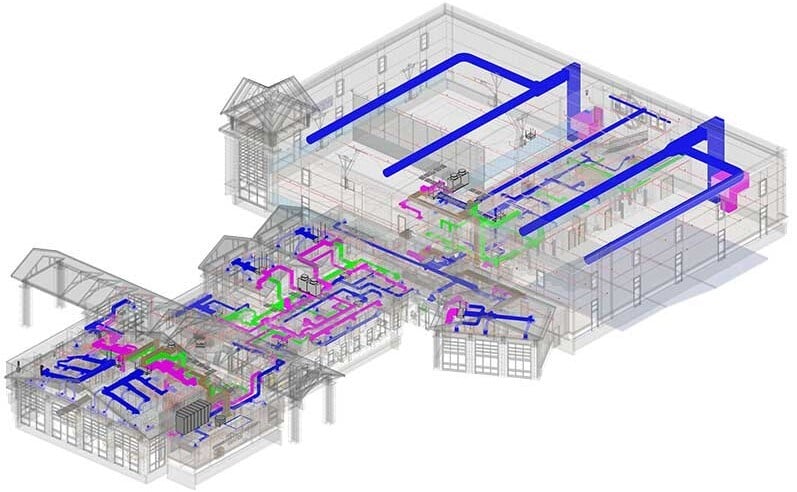

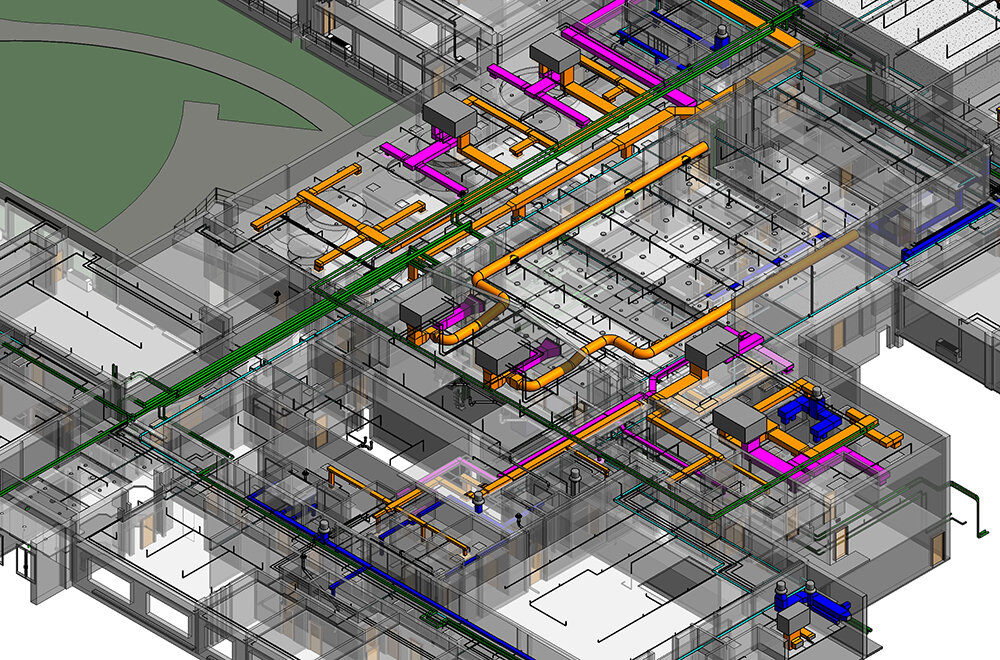

How BIM Supports Both Modular and Traditional MEP Implementations

BIM (Building Information Modeling) plays a central role in connecting design, coordination, and execution for both modular and traditional systems. Through BIM for MEP engineers, teams can digitally visualize every component, anticipate challenges, and improve MEP system efficiency.

BIM enhances both approaches by:

-

Streamlining coordination: Identifies design clashes early, supporting efficient workflows.

-

Improving accuracy: Integrates with MEP software to create precise fabrication drawings.

-

Enhancing collaboration: Encourages teamwork among architects, MEP engineers, and contractors for smoother delivery.

-

Supporting sustainability: Enables tracking of material usage for sustainable construction solutions.

-

Facilitating prefabrication: Strengthens digital tools supporting modular and traditional MEP, ensuring design-to-fabrication alignment.

-

Quality assurance: Maintains consistent standards through construction quality control in modular MEP projects.

These features show how BIM optimizes both traditional and modular workflows by combining innovation and practical execution. It also supports MEP workflow optimization using modular systems, ensuring higher accuracy and better coordination throughout every project phase, aligning with future trends in modular MEP systems that emphasize automation, sustainability, and smarter integration.

Conclusion

Modular MEP systems have transformed MEP engineering by improving precision, sustainability, and speed. While traditional MEP systems still serve projects that need flexibility, the modular approach offers measurable advantages.

When integrated with BIM for MEP engineers and advanced MEP software, both methods can achieve higher MEP system efficiency and better building services integration. Choosing between them depends on project scale, timelines, and design goals, but both remain vital to modern construction innovation.

Building the future of efficient, coordinated systems begins with mastering modern workflows. The BIM Course for MEP Engineers offered by Novatr helps professionals bridge engineering, BIM, and sustainable design practices for real-world impact.

Visit our resource page to learn how this course can strengthen your technical foundation and design confidence.

FAQs

1. What are the advantages of using modular MEP systems in construction projects?

Ans: They enable faster delivery, reduced material waste, and consistent quality through prefabrication. How modular MEP improves installation speed lies in simultaneous off-site and on-site work that enhances project efficiency and supports sustainable construction solutions.

2. How do traditional MEP systems compare in terms of cost and flexibility?

Ans: Traditional MEP systems have lower upfront costs but demand more on-site labor. They offer flexibility in adapting design changes but face the challenges of traditional MEP systems, such as schedule overruns and limited efficiency.

3. Which system offers faster installation and reduced project timelines?

Ans: Modular MEP systems provide the fastest installation due to pre-assembled modules and precise coordination. Combined with digital tools supporting modular and traditional MEP, they optimize performance and MEP workflow optimization using modular systems for smoother project completion.

Was this content helpful to you

.jpg)