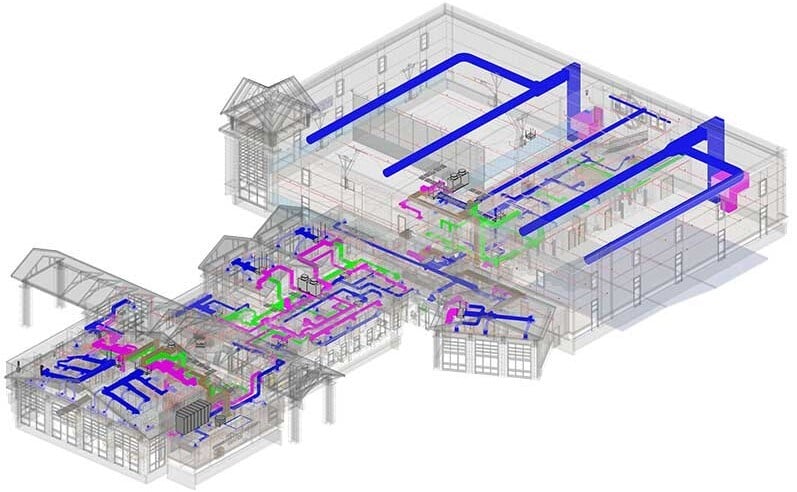

In the evolving world of digital construction, the role of a BIM mechanical modeller has become increasingly indispensable. These professionals are the creative force behind the 3D mechanical designs that form the backbone of every major building project today. Using advanced BIM software, they bring mechanical concepts to life, making sure everything from ventilation systems to heating networks fits together like a well-oiled machine.

With the rise in smart buildings and eco-conscious infrastructure, BIM mechanical modelling has shifted from being a niche skill to a must-have in the MEP industry. From working with architects and civil engineers to collaborating with plumbers and electricians, these professionals help unify all building components into a comprehensive digital model.

Employers across the globe are now seeking professionals who not only have technical proficiency but also a collaborative mindset. As projects grow in complexity, companies value those who can navigate MEP projects using coordinated and well-informed modelling practices. Knowing what to expect in an interview can give you a clear edge.

But to land a job as a BIM mechanical modeller, you need to ace the interview. Whether you're just starting out or moving up the ladder, this blog will help you understand the BIM mechanical modeller job description, prepare for the most common BIM mechanical modeller interview questions, and brush up on what recruiters expect.

BIM Mechanical Modeller Job Description

Q1: Which software tools do BIM mechanical modellers typically use?

Ans: The go-to tool is definitely Revit MEP, which is used for developing detailed mechanical models. However, many professionals also use Navisworks for clash detection and coordination, AutoCAD MEP for legacy designs, and BIM 360 for cloud collaboration. Staying updated with the latest tools is crucial in the BIM mechanical field.

Q2: What are the key responsibilities of a BIM mechanical modeller?

Ans: Their core tasks include:

- Developing and updating 3D models in Revit MEP

- Performing clash detection and resolving design conflicts

- Generating construction-ready drawings and quantity take-offs

- Collaborating with project stakeholders for smooth coordination

- Staying informed on trends in mechanical BIM services and BIM MEP services

Q3: What knowledge and skills are required for this role?

Ans: A strong understanding of MEP design principles is a must, along with knowledge of local building codes and sustainability guidelines. Proficiency in BIM software is non-negotiable. But that’s not all, attention to detail, organisational skills, and the ability to work in a multidisciplinary team are equally valued in the MEP industry.

Technical Knowledge & Tools

Q1: Which BIM tools are you proficient in?

Ans: I am most proficient in Revit MEP for mechanical modelling and use Navisworks for clash detection. Additionally, I have experience with AutoCAD MEP and BIM 360. These tools allow me to model HVAC, plumbing, and fire protection systems with precision.

Q2: What is your experience with creating families in Revit?

Ans: I have created multiple parametric families in Revit for various mechanical components, such as ducts, pumps, and diffusers. Creating custom families helps improve efficiency and accuracy, especially in large-scale MEP projects.

Q3: How do you ensure your models are clash-free?

Ans: I use Navisworks for clash detection and coordinate regularly with other teams. Early identification of clashes in the BIM mechanical model helps reduce rework during construction and ensures a smoother execution process.

Q4: Can you explain the importance of LOD in BIM modelling?

Ans: LOD, or Level of Development, defines how detailed a model element is at different stages. I ensure the appropriate LOD is applied throughout each project phase, from conceptual design to construction documentation.

Q5: How do you handle revisions and updates in your models?

Ans: I maintain a well-organised version control system and track all changes in the model. I communicate updates with the project team and ensure that the shared models reflect the latest information.

Experience-Based & Collaboration Questions

Q6: Describe a challenging project you worked on.

Ans: On a large commercial tower project, we faced tight spatial constraints for HVAC ducting. Using BIM software, I collaborated with electrical and plumbing teams to redesign layouts, avoiding structural conflicts. The result was a fully coordinated model that met all performance criteria.

Q7: How do you manage coordination with other disciplines?

Ans: I participate in weekly coordination meetings, share models on the common data environment, and use clash detection tools to identify issues. Open communication is key to successful collaboration in BIM MEP services.

Q8: Have you ever had to explain BIM concepts to non-technical stakeholders?

Ans: Yes. I often use visual walkthroughs and simplified diagrams to explain BIM mechanical concepts to clients or project managers. It helps them understand the benefits of BIM and contributes to better decision-making.

Q9: How do you stay updated with the latest BIM developments?

Ans: I regularly take MEP course updates, attend webinars, follow industry blogs, and participate in professional forums. Keeping up with trends helps me improve my workflow and deliver more value.

Q10: What is your process for quality control in your modelling work?

Ans: I follow a checklist approach, reviewing geometry, data accuracy, and model naming conventions. Peer reviews and internal audits are also part of our QC process.

Soft Skills & Real-World Application

Q11: How do you prioritise tasks during tight deadlines?

Ans: I create a task list based on deliverable timelines, break down large tasks, and tackle high-impact issues first. Efficient time management helps maintain productivity even under pressure.

Q12: How do you handle conflicts within a project team?

Ans: I approach conflicts with a collaborative mindset. I try to understand other perspectives, find common ground, and suggest solutions that meet technical and project goals.

Q13: What is your experience working in multidisciplinary environments?

Ans: I have worked on several projects with teams from architectural, structural, and MEP backgrounds. BIM naturally promotes cross-disciplinary collaboration, and I enjoy contributing to integrated project delivery.

Q14: How do you handle feedback or criticism about your work?

Ans: I take feedback constructively, analyse areas for improvement, and apply the suggestions to enhance future work. It is an opportunity to grow professionally.

Q15: Describe a time you helped improve a project process.

Ans: I once introduced a naming convention standard across our BIM models, which significantly improved coordination and reduced confusion during handovers.

Conclusion

The journey to becoming a successful BIM mechanical modeller involves more than just mastering tools; it is about understanding systems, thinking ahead, and working as part of a collaborative team. Interviewers look for professionals who can not only model efficiently but also communicate effectively, manage data, and adapt to evolving project needs.

By familiarising yourself with the typical BIM mechanical modeller interview questions and demonstrating your expertise in mechanical BIM services, MEP services, and tools like Revit MEP, you will set yourself apart in a growing and competitive field. For those aiming to specialise in MEP engineering, the BIM Professional Program for MEP Engineers by Novatr is a top choice. Whether you are entering the MEP industry for the first time or stepping up into a more senior role, preparation is your best asset.

Check out Novatr's Resource Page for the latest trends and updates!

Was this content helpful to you

.jpeg)

.png)