Effective planning in complex construction projects requires proactive strategies to address conflicts before they arise. Integrating systems early helps teams visualize potential conflicts, optimize layouts, and minimize rework. In large projects, MEP clash detection plays a pivotal role in identifying interference between mechanical, electrical, and plumbing elements, improving accuracy and maintaining project timelines without unnecessary delays or costly revisions.

Construction efficiency improves significantly when collaboration is prioritized among design and engineering teams. Understanding the role of design-build coordination in MEP projects ensures smoother integration of multiple disciplines, reducing errors during implementation. MEP design engineers in the USA earn an average salary of $88,150/year, emphasizing the expertise and precision required for successful project coordination.

What Is Design-Build Coordination And Why Is It Critical For MEP Projects?

Design-build coordination is a structured approach where design and construction teams work closely from the early stages of a project. It integrates architectural, structural, and systems planning to streamline execution and reduce conflicts. By aligning objectives and schedules, it enhances efficiency and decision-making. In this process, a well-defined MEP coordination workflow ensures all systems are planned, reviewed, and adjusted collaboratively before construction begins.

Here is why design-build coordination is critical for MEP projects:

-

Identifies conflicts between systems early, preventing costly rework during construction.

-

Enables accurate scheduling and sequencing of tasks to optimize project flow.

-

Promotes alignment between contractors and engineers, reducing miscommunication errors.

-

Enhances risk mitigation by addressing potential safety or compliance issues before implementation.

-

Supports consistent documentation and tracking of design changes for accountability.

-

Strengthens construction project collaboration by connecting all disciplines in a unified workflow.

How Do MEP Clashes Occur Between HVAC, Plumbing, And Electrical Systems?

In complex construction projects, overlapping systems and dense infrastructure often create coordination challenges. Integrating designs without a thorough review can result in clashes between HVAC, plumbing, and electrical layouts. Careful alignment during early stages helps reduce these clashes, while proper pre-construction planning allows teams to anticipate spatial constraints and system interdependencies before execution, improving efficiency and reducing unexpected delays.

Here is why MEP clashes typically occur and what contributes to them:

-

Overlapping ductwork and piping routes create physical clashes in shared spaces.

-

Limited spacing between electrical conduits and plumbing lines can cause installation conflicts.

-

Late design changes may disrupt layouts that were already planned.

-

Poor communication between contractors increases the chance of errors.

-

Lack of building services coordination can prevent proper system placement and planning.

-

Inadequate MEP design optimization can result in conflicts and inefficient layouts.

Also Read: Top 10 MEP Engineering Courses in India 2026

What Are The Consequences Of Unresolved MEP Clashes On Time, Cost, And Safety?

Unresolved MEP clashes can have significant effects on construction projects, affecting multiple aspects of execution. These issues often lead to delays, cost overruns, and operational inefficiencies. By overlooking potential conflicts during planning, teams face challenges in coordination, rework, and compliance. Properly evaluating the impact of clash detection on construction efficiency can help prevent these setbacks and maintain project performance.

The consequences of unresolved MEP clashes are as follows:

-

Project delays occur as teams stop work to resolve unexpected conflicts.

-

Increased labor costs result from rework and extended timelines.

-

Material wastage rises when components must be modified or replaced.

-

Safety risks increase due to unplanned adjustments in occupied or restricted spaces.

-

Reduced overall quality emerges when systems are forced to fit rather than designed cohesively.

-

Poor MEP system integration leads to operational inefficiencies and long-term maintenance issues.

Which Strategies And Tools Help Identify And Resolve Clashes Before Construction?

Addressing potential conflicts before construction begins requires careful planning and coordination across all design and engineering teams. Early engagement and collaborative reviews identify issues and align system layouts. With structured processes and consistent communication, MEP design optimization becomes more effective throughout the construction lifecycle.

Here are the strategies and tools for managing MEP clashes in design-build projects:

-

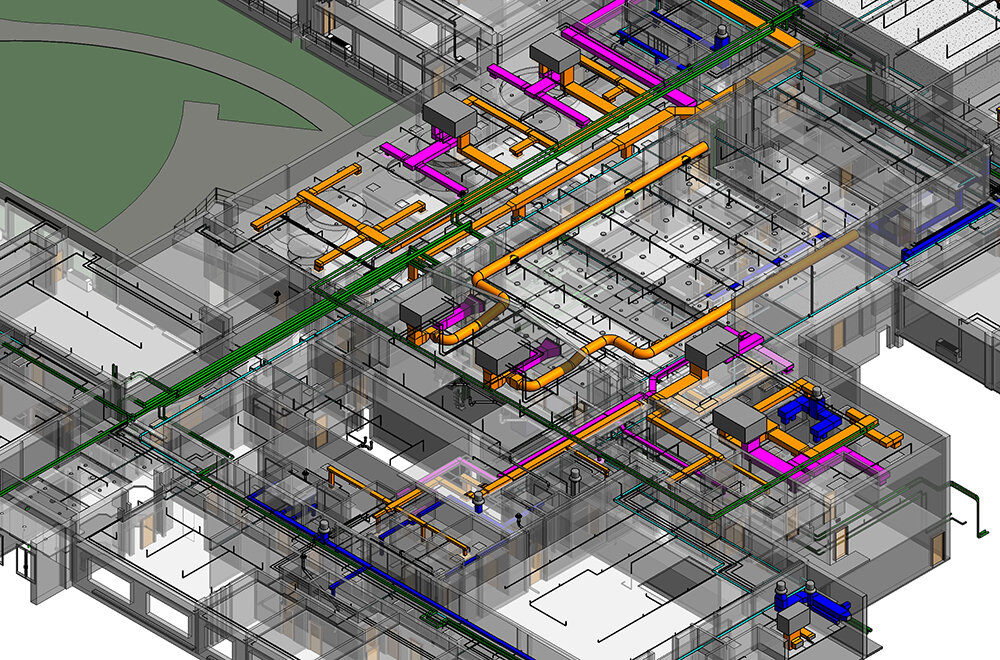

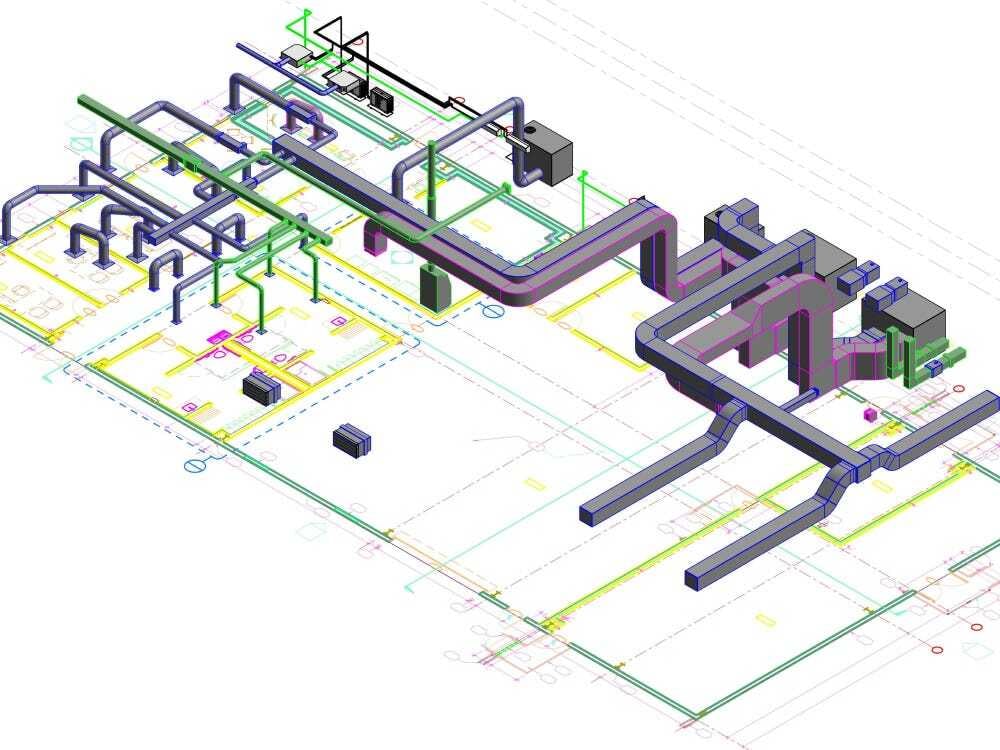

BIM software allows teams to model systems in 3D and detect clashes before installation.

-

Design coordination meetings enable cross-disciplinary teams to identify and resolve conflicts early.

-

Clash detection modules highlight potential interference points automatically for review.

-

Integrated workflow processes provide structured steps for evaluating and addressing detected clashes.

-

Project scheduling platforms help align installation sequences to avoid overlapping work and delays.

-

Early stakeholder involvement demonstrates how early planning enhances project delivery, ensuring smoother system integration.

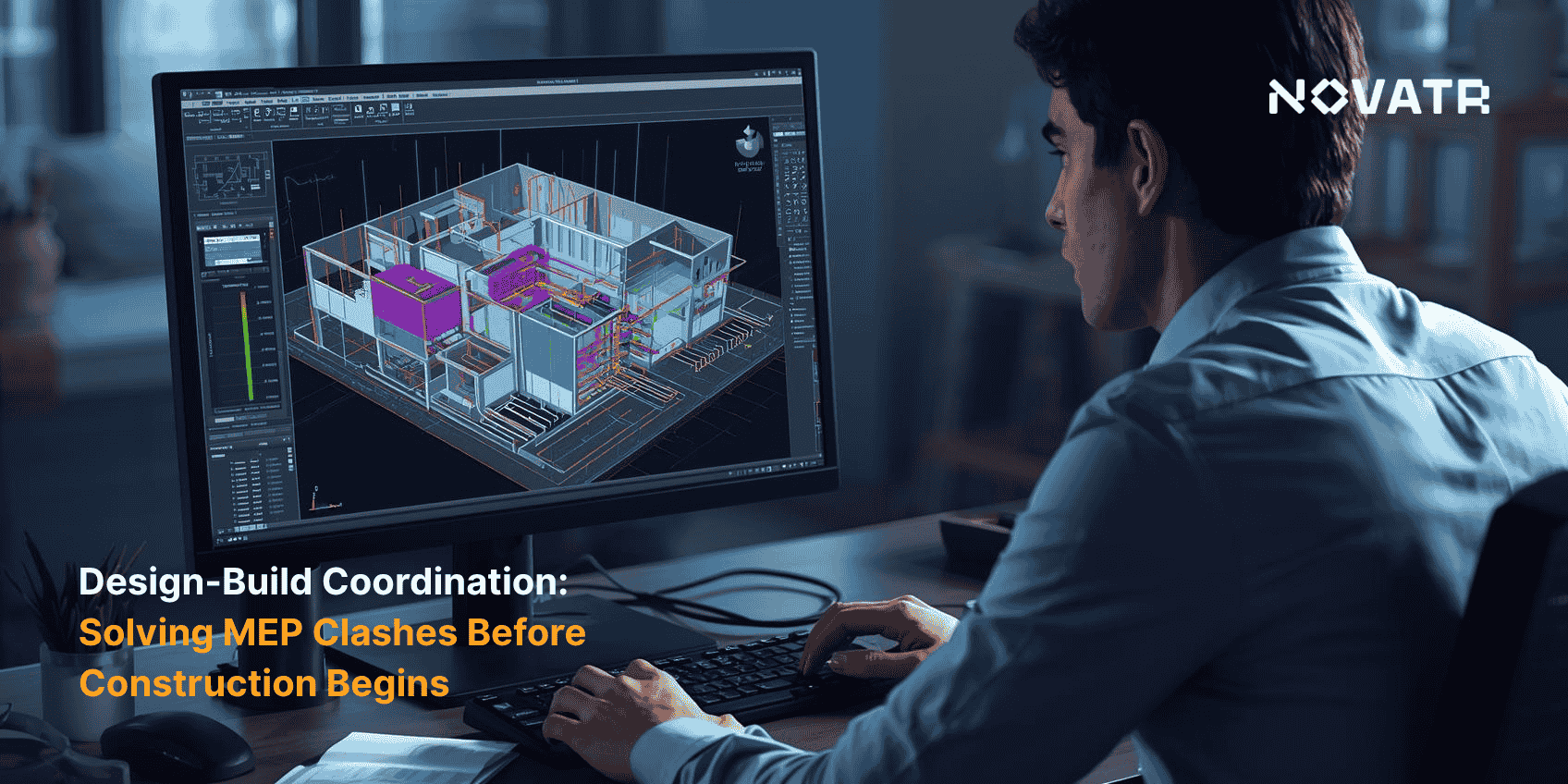

How Does BIM Streamline Clash Detection, Coordination, And Collaboration Among Teams?

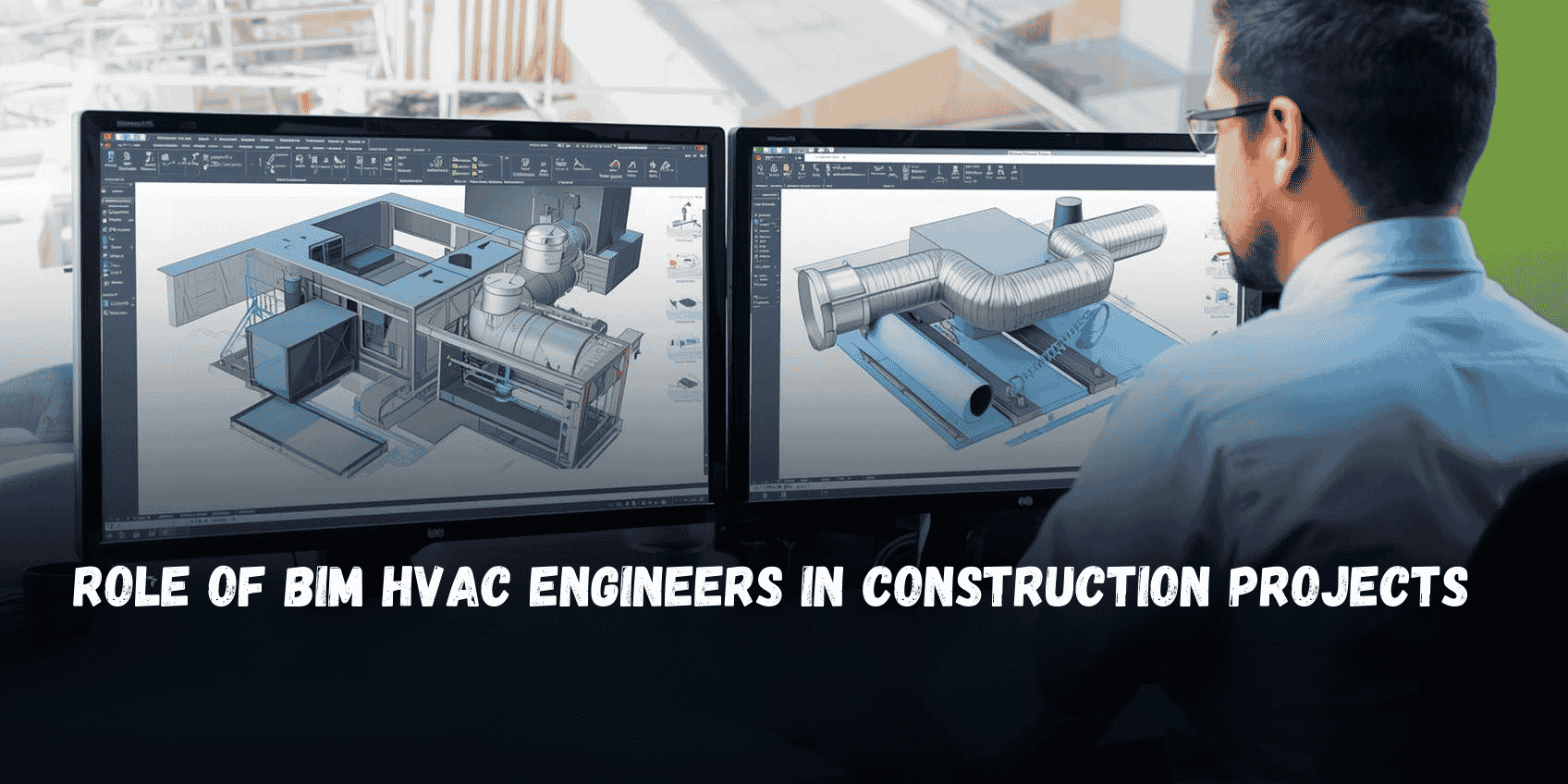

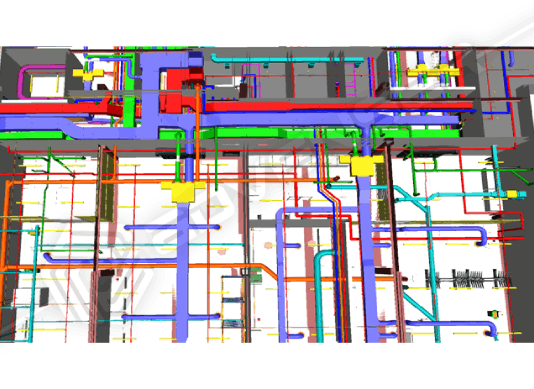

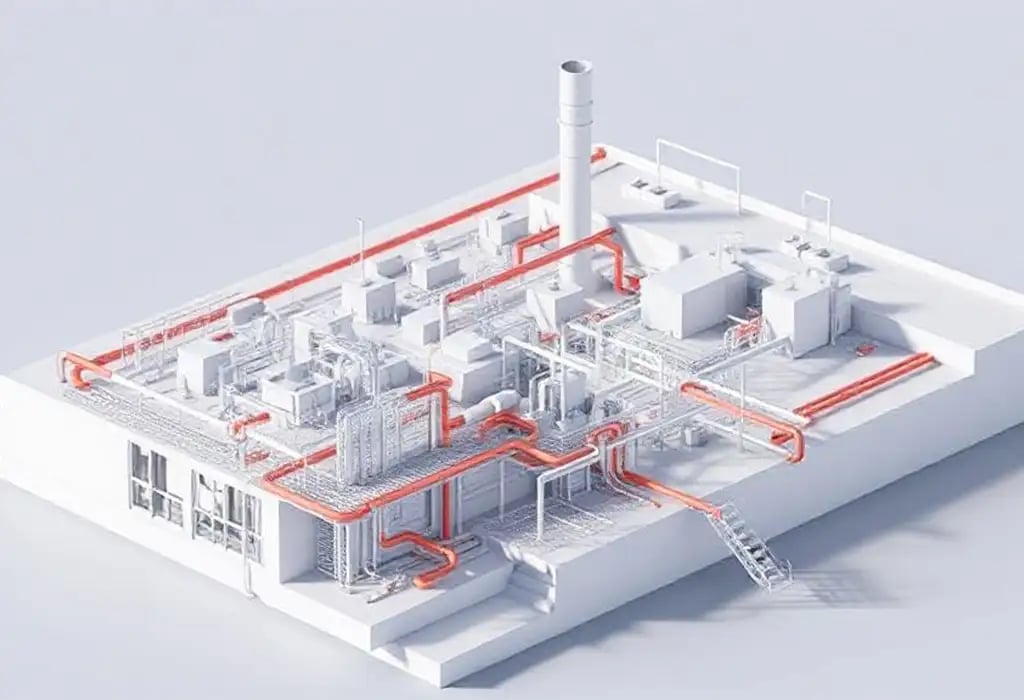

BIM enables teams to visualize and simulate complex systems before construction begins, reducing potential conflicts and improving alignment across disciplines. By integrating data from multiple stakeholders, teams can review designs, adjust layouts, and anticipate issues early. Using MEP software within BIM enhances accuracy and efficiency, supporting smoother communication, better planning, and proactive resolution of conflicts among project teams.

Here is how BIM supports clash detection, coordination, and collaboration for MEP projects:

-

3D modeling enables teams to visualize all systems in detail, detecting potential clashes before installation occurs.

-

Collaborative design review allows cross-disciplinary teams to discuss, adjust, and resolve conflicts efficiently before construction.

-

Automated clash detection highlights system interferences instantly, reducing errors and speeding up the decision-making process.

-

Workflow integration ensures structured evaluation of designs, maintaining consistency across multiple engineering and design teams.

-

Project management tools track modifications, improve accountability, and ensure all team members remain updated, emphasizing the importance of team collaboration in MEP coordination

-

Early adoption shows how BIM for MEP engineers improves collaboration, reduces conflicts, and ensures smoother project execution.

Conclusion

Effective design-build coordination ensures that MEP systems are thoroughly reviewed and aligned before construction begins. By incorporating structured workflows and proactive planning, teams can reduce errors, minimize delays, and improve overall project efficiency. Implementing how BIM improves MEP collaboration before construction and leveraging insights from MEP engineering further strengthens coordination, enabling precise execution and supporting informed decision-making across all project disciplines.

For enhanced learning and practical skills, the BIM Course for MEP Engineers offered by Novatr provides comprehensive training in advanced modeling and clash resolution. Integrating lessons from this program into projects supports BIM clash management, improves system integration, and promotes effective collaboration. Visit our resource page to explore detailed guides, tools, and case studies for better design-build coordination and MEP clash management practices.

FAQs

1. What are MEP clashes and why do they occur in construction projects?

Ans: MEP clashes happen when mechanical, electrical, or plumbing systems overlap or interfere within the same space. They usually occur due to limited spatial planning, late design changes, or poor coordination between contractors and engineers. These clashes can cause delays, increase costs, and complicate installation if not addressed early.

2. How does design-build coordination help prevent MEP clashes?

Ans: Design-build coordination aligns design and construction teams from the project’s start. By reviewing layouts together and synchronizing schedules, teams can identify conflicts early. This proactive collaboration reduces errors, avoids costly rework, and ensures that systems are installed efficiently and safely.

3. What role does BIM play in detecting MEP clashes early?

Ans: BIM allows teams to create detailed 3D models of all building systems. It identifies spatial conflicts before construction, enabling adjustments in the design phase. By providing a visual, collaborative platform, BIM helps improve accuracy, streamline planning, and minimize delays caused by unforeseen clashes.

Was this content helpful to you

.jpg)

-1.png)