Designing MEP systems for cold storage and food processing units requires precise control of temperature, humidity, and airflow. Focusing on energy-efficient cold storage reduces operational costs while keeping products safe. In the USA, MEP engineers earn an average salary of $101,752, reflecting the expertise needed to plan, coordinate, and maintain these specialized systems.

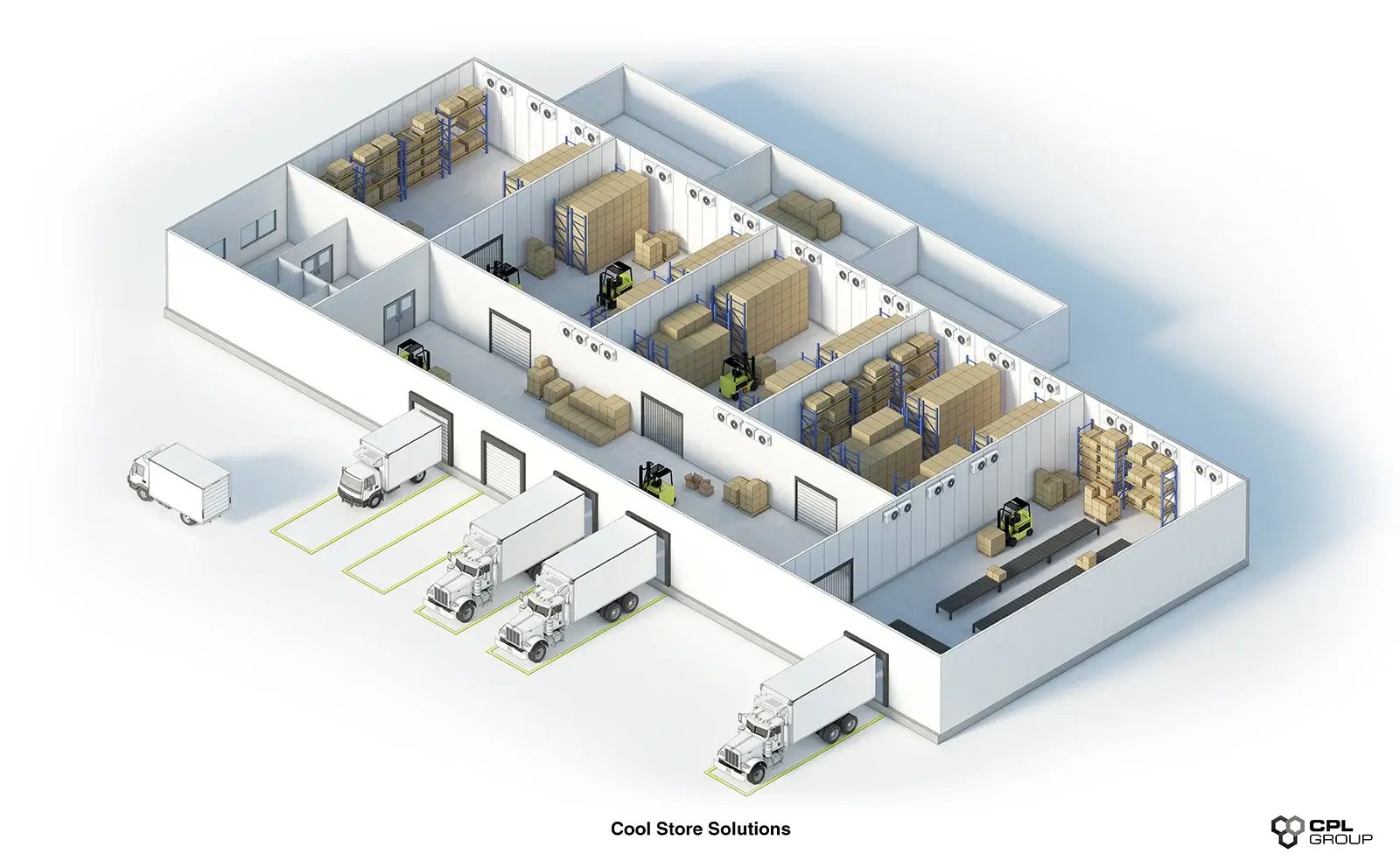

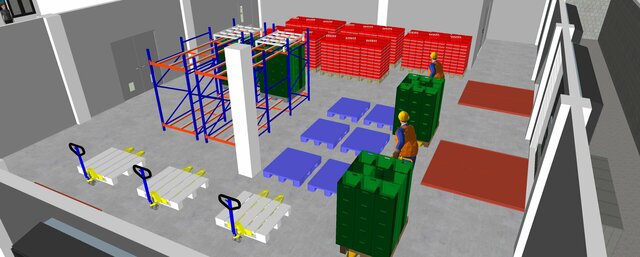

Proper planning ensures that all systems work together seamlessly. Using MEP integration in food processing improves equipment placement and workflow efficiency. Engineers can design layouts that save energy, support sustainable operations, and comply with industry standards, making cold storage and food processing facilities reliable and efficient without compromising performance or safety.

Why Is Designing MEP Systems For Cold Storage And Food Processing Units Unique And Challenging

Maintaining precise environmental conditions requires careful coordination of airflow, temperature, and humidity. Integrating reliable refrigeration, plumbing, and electrical systems adds complexity, especially when optimizing for energy use. Incorporating a temperature-controlled storage design ensures consistent quality and operational efficiency. The combination of strict regulatory standards, space limitations, and equipment requirements makes planning and execution highly specialized, demanding expert technical knowledge and meticulous attention to detail.

The uniqueness and complexity of these systems arise from several key factors:

-

Cooling systems must handle large volumes while maintaining consistent temperatures for various storage needs simultaneously.

-

Equipment relies heavily on uninterrupted power and precise operation, making downtime or failure highly impactful on facility performance.

-

Limited space requires careful planning to place refrigeration, electrical, and plumbing systems without obstructing maintenance access.

-

Multiple systems must function together smoothly, ensuring no interference between airflow, temperature control, and electrical components.

-

Safety, hygiene, and workflow efficiency must be maintained in food processing facility design, increasing system design complexity.

What Are The Key HVAC, Plumbing, And Electrical Requirements For These Facilities?

Cold storage and food processing facilities require precisely engineered systems to regulate temperature, humidity, and airflow. Effective integration of refrigeration, ventilation, and power systems is essential to maintain product quality, optimize energy use, and ensure safe, reliable operations.Integrating HVAC for cold storage supports consistent cooling performance while minimizing energy use. These facilities require robust plumbing, electrical, and control systems tailored to the unique needs of perishable goods and sensitive processing environments.

Key requirements for these systems include:

-

Efficient airflow distribution and temperature control to maintain uniform conditions throughout storage and processing areas.

-

Reliable backup power and electrical circuits to prevent disruptions in refrigeration, lighting, and machinery operation.

-

Proper insulation, ducting, and ventilation design to reduce energy loss and maintain consistent cooling.

-

Safe and hygienic plumbing systems in food units to support water supply, drainage, and sanitation requirements.

-

Integration of monitoring and control systems ensures efficient operation of HVAC solutions for temperature-controlled storage, refrigeration, and electrical equipment in real-time.

-

Compliance with building codes and industry standards for safety, sanitation, and energy efficiency in facility operations.

Also Read: Boost Your MEP Engineering Career with BIM Mastery

How Do Temperature Control And Humidity Management Affect System Design?

Maintaining precise temperature and humidity directly influences the efficiency and reliability of cold storage and food processing facilities. Proper environmental control ensures product quality while reducing energy waste. Applying how to optimize energy consumption in cold storage units allows designers to balance cooling requirements with operational costs, shaping system layout, equipment selection, and control strategies.

The following factors illustrate how temperature and humidity impact system design:

-

Uniform airflow planning ensures consistent temperatures and prevents hot or cold spots that could compromise product quality.

-

Proper equipment sizing with energy-efficient refrigeration systems for industrial buildings accommodates varying thermal loads, maintaining efficiency without overstraining ventilation units.

-

Insulation and moisture barriers directly influence humidity control, preventing condensation and protecting facility interiors and stored goods.

-

Advanced monitoring and control systems allow real-time adjustments, maintaining precise environmental conditions across all zones.

-

Material and surface selection is affected by humidity levels to ensure hygiene, durability, and resistance to moisture-related damage.

-

Implementing MEP design guidelines for food processing plants ensures stable temperature and humidity control throughout the facility.

What Role Do Energy Efficiency And Sustainability Play In MEP Planning For These Units?

Energy efficiency and sustainability are central to designing MEP systems for cold storage and food processing facilities. Optimized energy use reduces operational costs while supporting long-term environmental goals. The role of MEP engineers in cold storage design ensures that HVAC, plumbing, and electrical systems are planned with efficiency, reliability, and sustainability in mind, delivering consistent performance and minimizing waste throughout the facility.

These factors demonstrate the role energy efficiency and sustainability play in MEP planning:

-

Reducing energy consumption through strategic system layouts and equipment placement to minimize waste.

-

Implementing renewable energy solutions and low-impact technologies to lower environmental footprint.

-

Designing efficient water and waste management systems to support sustainable industrial buildings.

-

Selecting durable materials and components to reduce maintenance, replacements, and environmental impact.

-

Monitoring and adjusting environmental conditions to enhance product quality and the impact of proper MEP design on shelf life and storage efficiency.

-

Integrating automation and advanced controls to optimize operations while supporting sustainability objectives.

How Does BIM Help In Designing, Coordinating, And Optimizing MEP Systems For Cold Storage And Food Processing?

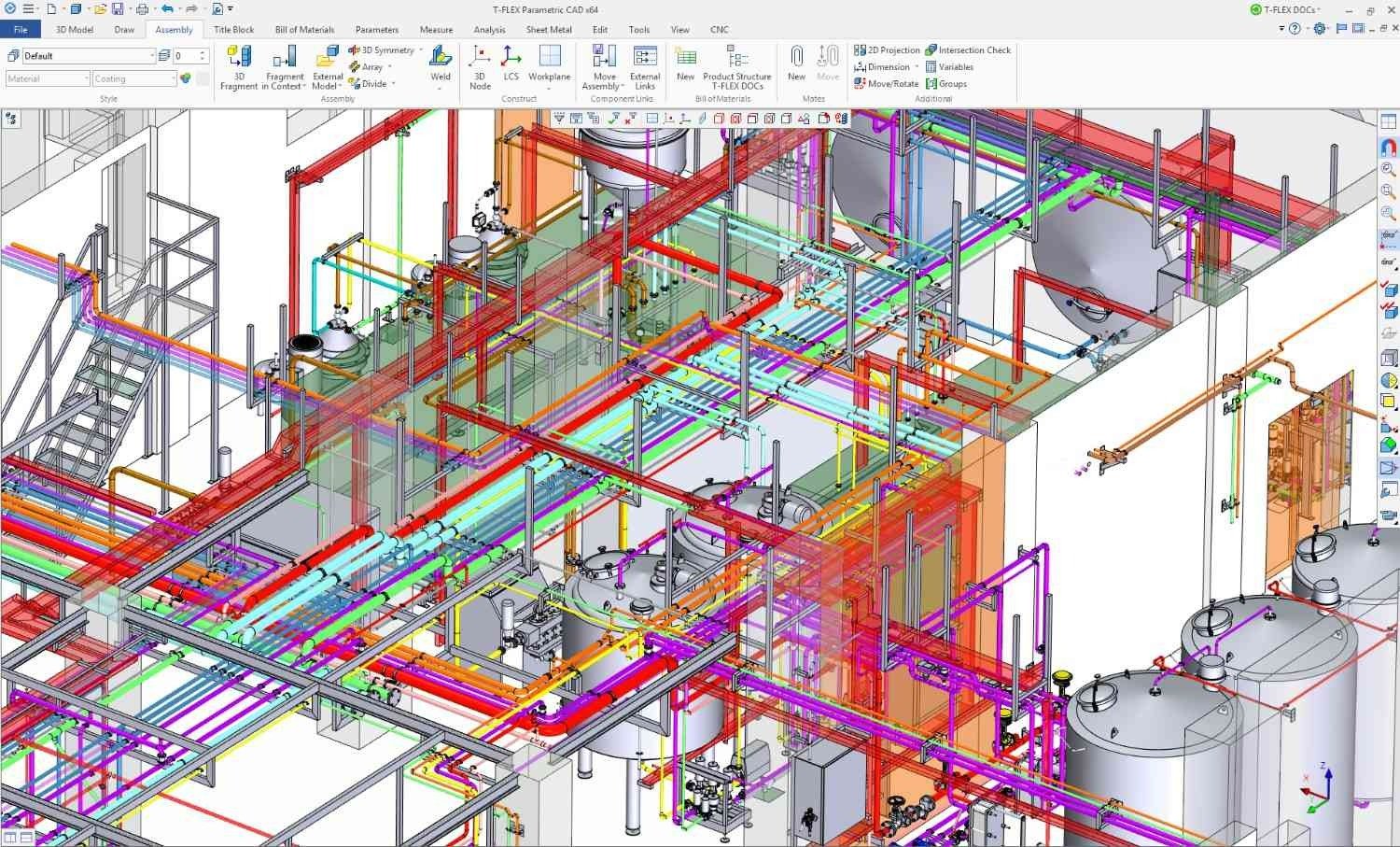

BIM provides a digital platform to visualize, plan, and manage complex MEP systems in cold storage and food processing facilities. It enables precise coordination between HVAC, plumbing, and electrical components, reducing clashes and errors during construction. Using MEP software allows engineers to simulate performance, optimize layouts, and ensure systems operate efficiently, saving time and improving overall facility management.

Key ways BIM supports MEP systems for cold storage and food processing include:

-

Creates a detailed 3D representation of all MEP systems, enabling precise alignment of refrigeration, plumbing, and electrical layouts.

-

Detects potential conflicts between ducts, piping, and electrical conduits before construction begins, minimizing rework and delays.

-

Simulates airflow and temperature distribution to ensure optimal performance of cold storage zones and processing areas.

-

Facilitates coordinated scheduling for installation, ensuring critical refrigeration and HVAC components are installed efficiently.

-

Provides analytical tools for BIM for MEP engineers to assess energy use, cooling efficiency, and system performance.

-

Supports operational monitoring and predictive maintenance, enabling efficient temperature and humidity control and showing how MEP engineers manage operational efficiency in food processing.

Conclusion

Designing MEP systems for cold storage and food processing units requires careful coordination of multiple components to maintain efficiency, safety, and consistent product quality. Thoughtful refrigeration system design ensures temperature stability and energy optimization, while integrating monitoring and control strategies helps reduce operational risks. Attention to airflow, humidity, and energy use creates facilities that operate sustainably.

Advanced planning also considers sustainability and operational efficiency, highlighting the importance of plumbing and water supply in food processing units for hygiene and resource management. Professionals can enhance skills through programs like the BIM Course for MEP Engineers offered by Novatr. For additional insights, visit our resource page to explore tools, guidelines, and best practices for effective MEP system planning and design.

FAQs

1. How does temperature control impact HVAC design in food processing facilities?

Ans: Temperature control determines airflow, insulation, and system capacity to maintain stable processing conditions and product safety.

2. What role do refrigeration systems play in MEP design for cold storage?

Ans: Refrigeration systems regulate temperature consistency and energy efficiency, forming the core of cold storage performance and reliability.

3. How are electrical systems planned to handle high energy demands?

Ans: Electrical systems are designed with load management, redundancy, and safety measures to support continuous and efficient equipment operation.

Was this content helpful to you

.jpg)

.png)